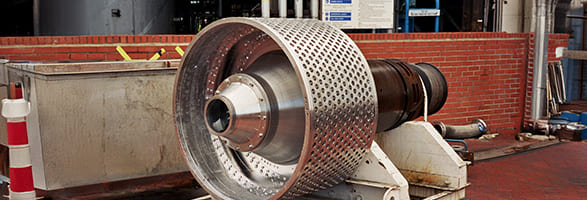

High Efficiency Centrifuge Baskets and Screens

In the dynamic landscape of industrial processes, centrifuges stand as vital workhorses, ensuring the precise separation of materials for diverse applications. At the heart of our offerings lie world class specialist screens and optimised engineering solutions designed to enhance the performance of industrial centrifuges.

Although industrial centrifuges have existed in various forms for over a century, it is only in the last 50 years that they have truly gained prominence.

Significant developments in CFL manufacturing technology and the availability of superior construction materials have greatly enhanced screen mechanical properties, resulting in superior resistance to abrasion, erosion and corrosion.

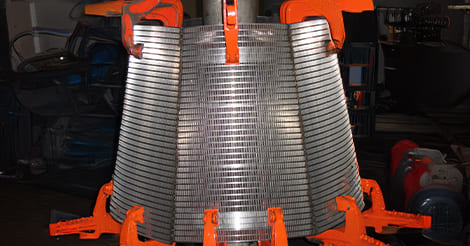

Engineering prowess is the cornerstone of the efficiencies and machine optimisation offered by CFL screens. Through engineered excellence and precision fabrication, CFL baskets and screens promote reduced vibration and turbulence, resulting in a highly improved coefficient of friction. This translates directly into reduced final solid surface moisture and lower energy consumption.

The efficiencies embedded in CFL centrifuge screens and baskets extend far beyond precise separation. They represent a strategic investment in energy savings, operational cost reductions, increased throughput, and environmental sustainability. By choosing our products, industries not only optimise centrifuge operations but also pave the way for a more efficient, cost effective, and environmentally sustainable future.

CFL centrifuge screens and baskets are designed and engineered to directly retrofit into a number of industrial centrifuges without the need for any modifications. These include pusher, screen bowl decanter, screen scroll, peeler, and vibratory machines. OEM machines compatible with CFL products include Krauss Maffei, Siebtechnik, Tema, Broadbent, Bird, KHD, Humboldt, Escher-Wyss, and Alfa-Laval.

We continuously develop and enhance the design of our centrifuge baskets and screens to provide our clients with solutions that not only improve operational performance and reduce costs, but also promote environmental responsibility. Through continuous innovation and collaboration with our clients, CFL aims to drive positive change and contribute to a more sustainable future.

Mechanical Advantages of CFL’s Centrifuge Baskets and Screens

- Reduced downtime

- Improved overall screen life

- Proprietary profile wire with unique wear zone

- Precision fabrication, ensuring basket concentricity

- Lightweight construction with high mechanical strength

- Fully welded construction maintained throughout operating life

- Increased centrifuge life due to smoother operation and performance

Process Advantages of CFL’s Centrifuge Baskets and Screens

- Precision fabrication, ensuring even balance during operation and reduced vibration through the rotating assembly

- Lowered coefficient of friction, leading to reduced motor power requirements and conveyance torque

- Improved dewatering with minimised final solid surface moisture

- Reduction in possible downstream energy drying costs

- Superior bedding, resulting in even cake distribution

- Balanced wear of screen apertures

- Increased % open area

- Increased throughput

High Integrity Centrifuge Baskets and Screens for Industrial Centrifuges

Key Benefits & Features

- Fully welded structure

- Energy saving performance

- Long wear life

- Reduced downtime

- Highly efficient dewatering

- Lightweight construction

- Available in abrasion and erosion resistance materials

- Retrofit directly into existing equipment, with no modifications

- Full engineering technical support

Industrial Applications

- Salt washeries

- Sugar production

- Mineral production

- Cement production

- Fertiliser production

- Chemical production

- Coal and coke washeries

- Paper and pulp industries

- Food processing industries