Reliable Polymeric Liquid and Gas Filter Cartridges

CFL provides technical and practical solutions for the filtration, separation and purification of liquids and gases across various applications. Our products deliver enhanced performance and reliability, even in the most demanding environments, ensuring maximum product throughput and efficiency.

Filter cartridges are essential components in many industrial filtration systems.

At Carbis, we specialise in providing high-performance filter cartridges designed for a wide range of applications across various industries. Unlike general-purpose filters, our products are engineered to meet the rigorous demands of industrial, process, food, beverage, and pharmaceutical applications.

Our standard range includes filters made from high-quality materials such as Polypropylene, Nylon, Polyester, Glass Fibre, PES, PTFE, PPS, Cotton, and Stainless Steel.

These materials are selected for their durability, chemical resistance, and ability to withstand harsh operating conditions. Carbis filter cartridges are available in various lengths, diameters, and micron ratings to accommodate both coarse and fine filtration requirements.

For more information or to discuss your specific filtration needs, contact Carbis today. We have the right filter cartridge for your application, no matter how challenging.

Typical Applications

Fine chemicals

The batch filtration of chemicals and reagents, including chemical effluents before disposal and water treatment.

Semiconductors

The preparation of process waters and chemicals used to manufacture semiconductors and other electronic components.

Coatings and inks

The pre-filtration of paints prior to recovery by RO on electro-deposition paint lines and the filtration of water based inks for high speed inkjet and spray printers.

Electroplating solutions

The filtration of electroplating bath solutions to improve plating quality, and the restoration of plating solutions, including the recovery of precious metals.

Food and beverages

The clarification of foods and beverages, including syrups, beers, wines and spirits.

Process water systems

The filtration of process water in pure water supply systems.

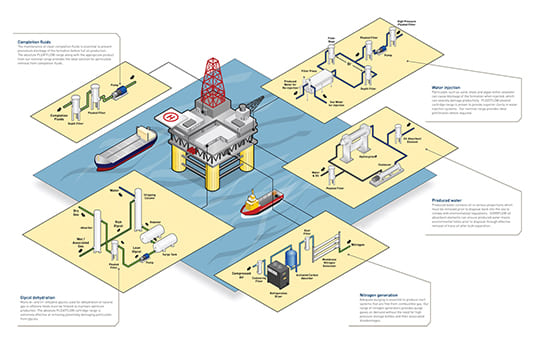

Enhanced oil recovery techniques

The filtration of water-based fluids, such as oil field brines, for use in the completion of workover fluids by the oil and gas industry.

Hydrocarbon removal

The reduction of dispersed and dissolved hydrocarbons from produced water.

Specialist Industries

OIL AND GAS

Our portfolio contains a wide range of depth and pleated filter cartridges, and specialist filter internals engineered to provide the optimal product for key applications for upstream and downstream operations. Our products are used in many critical applications, including produced water treatment, sulphate removal, injection water treatment, catalyst bed protection and gas separation.

CHEMICALS AND PHARMACEUTICALS

In the intricate world of industrial processes, the efficiency and reliability of filtration systems are paramount. Our commitment to excellence is epitomised by our specialist filter internals and process equipment, meticulously engineered to redefine the standards of precision, durability, and performance.

CFL customised engineered solutions assist in addressing the unique challenges of chemical and pharmaceutical applications, our products seamlessly integrate into diverse industrial processes, providing optimal performance in any application.

FOOD AND BEVERAGE

CFL offers a range of robust and cost effective solutions and products suitable for pre and final filtration of various process liquids and gases. In food processing, where precision, safety, and quality are non-negotiable, CFL specialist filtration and separation products and equipment take centre stage. Engineered with the highest standards of hygiene and efficiency in mind, our products redefine the landscape of filtration for the food industry.

WATER TREATMENT

CFL has supplied equipment and specialist internals to the water treatment industry for more than four decades. Our products are supplied globally for applications such as ion exchange, produced water treatment, desalination, purified water supply, demineralised water supply, municipal and industrial water treatment. We offer our clients uncompromised engineered solutions with unrivalled knowledge and expertise.

Process Design with Engineering Excellence

CFL is committed to delivering quality engineered solutions that address the ever evolving demands of industrial processes. We design, develop and manufacture to the highest of standards in order to meet the specific challenges and objectives set by our clients.

Key Benefits & Features

- Exceptional filtration efficiency

- Extended service life

- Customised solutions

- Optimized process efficiency

- Compatible with industry standards

- Exceptional technical support

Industrial Applications

- Pharmaceutical and chemical preparations

- Brewing and food production

- Produced water treatment

- Process water treatment

- MEG and TEG purification

- Injection water treatment

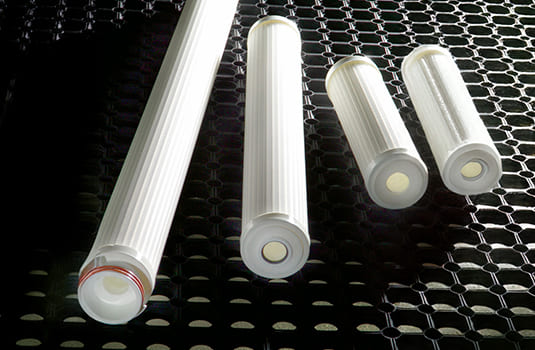

The CFL Standard Range of Liquid and Gas Filter Cartridges

LiQiFlowMX®

Industries served: Oil and gas, refining, water treatment and bulk chemicals

LiQiFlow®

Industries served: Oil and gas

REMivol PLUS®

CFL REMivol PLUS is a combined hydrocarbon and particulate removal filter with a unique design that combines the benefits of an absolute rated filter for particulate removal, helping to extend the service life of the REMivol hydrocarbon removal media.

CFL REMivol hydrocarbon removal cartridges differ from those offered by other manufacturers, where hydrocarbons are removed through surface adsorption. REMivol employs a proprietary surface modified substrate composed of selected fibres, chemically modified to provide a high affinity to form a powerful electro chemical bond with hydrocarbons. No leaching or migration of hydrocarbons.

Industries served: Oil and gas, general process and water treatment

LiQiFlowS®

Absolute rated filter cartridges, employing either glass fibre or polypropylene filter media. Thermally bonded guaranteeing cartridge integrity and providing unrivalled chemical compatibility and performance. Robust polypropylene hardware ensures durability and reliability in many critical applications.

Industries served: Chemicals, pharmaceuticals, general process, food and beverage.

MetFlow® - CFL Metallic Filter Cartridges

CFL fully welded MetFlow metallic filter cartridges are ideal for harsh operational environments and aggressive fluids and gases. Offered to directly retrofit into existing equipment without the need for any modifications, CFL metallic filter cartridges contribute to sustainability by reducing the need for frequent replacements. CFL offers innovative, specialised solutions for complex and demanding process requirements, including high pressure, high temperature, and corrosive conditions.

Our metallic cartridges embody a commitment to durability, sustainability, cost efficiency, and unmatched performance across diverse industrial sectors. Crafted from 100% recyclable materials, they significantly reduce environmental impact, supporting the journey to net zero attainment for both our clients and our business.

Cleanability is a crucial feature of CFL metallic filter cartridges. By applying the correct regenerative processes, our products extend service life and enable repeat use, resulting in improved plant economics, increased campaign programs and reduced operating costs, actively promoting sustainability and reducing environmental impact.

Industries served: Oil and gas, chemicals, pharmaceuticals, food and beverage, water treatment, general processes

Standard Specifications of CFL Liquid and Gas Filter Cartridges

Our performance driven designs ensure you get products that stand the test of time.

We design, engineer and deliver.

CFL Polymeric cartridges

- Nominal diameter options - 63.5 to 158.6 mm

- Filter media options - Polypropylene, Glass, PTFE, PES and Nylon

- Nominal length options - 254 to 1524 mm

- End Cap options - 222 flat, 222 spear, 226 flat, 226 spear and DOE

MetFlow® - Metallic filter cartridges

- Nominal and absolute micron ratings - 0.3 to 1000 micron

- Nominal diameter options - 25 to 500 mm

- Nominal length variants - 125, 254, 508, 762, 1000 mm, with custom lengths from 60 to 2000 mm

- Filter media options - CFL SintAbond™ materials, wire cloth, metal fibre, CFL profile wedge wire. Standard materials 316SS, alloy C276 and titanium Gr2.