High Integrity Filter Vessels, Housings and Process Equipment

Customised engineered solutions, delivered with an intrinsic understanding of industrial processes, uniting safety, performance and decades of technical expertise. CFL designs and manufactures specialist high-integrity industrial filter vessels, housings, process equipment and associated internals, providing protection to valuable assets and the environment.

With the ever increasing demands for maximum efficiency and throughput, process equipment and systems have evolved to meet increasingly sophisticated operational and environmental requirements. CFL offers advanced engineered solutions that contribute to a better, more sustainable world.

Filter vessels and specialist process equipment are integral components to modern-day process plants, playing crucial roles in various industries, contributing to the efficiency, safety, and reliability of industrial processes. CFL provides expertise in the process and mechanical design and manufacture of specialist filtration and separation equipment. CFL equipment is specifically designed for the removal of contaminants from liquids and gases, contributing to overall plant efficiency and optimisation.

CFL possesses rich expertise in fabricating vessels, filter housings and related process equipment and piping. Our welders are coded with third-party approval to international standards, including EN287 and ASME IX, covering a variety of austenitic, super austenitic and nickel alloys.

We are approved and accredited by several internationally recognised accreditation bodies, operators and end-users. With decades of history and experience supplying equipment to high-profile projects globally, CFL has established itself as a trusted partner to industry.

CFL operates a system of continuous improvement, covering the quality and sustainability of our products, equipment, and services, whilst protecting people and the environment. CFL is actively committed to the enforcement of our QHSE policies, protecting human health, ensuring operational safety, preventing pollution and adverse environmental impact.

This commitment enables us to provide our clients with safe and high quality products and equipment.

As you would expect, our business adheres to industry BS standards:

The CFL quality management system is certified to:

BS EN ISO 9001:2015

Policies and practices operate fully in accordance with:

BS EN ISO 3834-2:2021

BS EN ISO 45001:2018

BS EN ISO 14001:2015.

We also hold accreditation with:

Achilles Oil and Gas Europe

Proactis

Avetta.

Complementing our core competencies, we provide a number of in-house services and testing, including CSWIP Level 3.0 welding inspection, PMI, Fischer Feritscope® testing, penetrant testing, hydrostatic testing, mechanical fitting and inspection, including refurbishment and overhaul of filtration and separation equipment, process internals and associated equipment.

Precision Engineered Brilliance

Our commitment to quality, integrity and innovation, allows us to deliver precision engineered excellence, with trusted solutions helping industry remain in control of critical processes. Our vast experience and decades of engineering know-how are testament to our abilities. We strive for perfection in all that we do, upholding the highest of standards in all our operations, this attention to detail makes us your reliable and trusted partner.

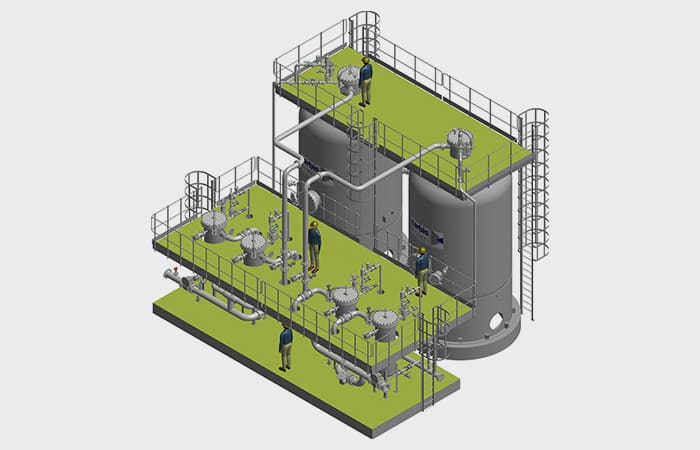

We provide solutions incorporating a range of standard and non-standard custom manufactured vessels, housings, process internals and associated equipment. Our experienced team will provide full support, from conceptualisation, engineering and project management, through to execution.

Standard Filter Vessels and Housings

CFL standard filter housings and vessels are meticulously crafted to meet the requirements of general-purpose industrial applications. They consist of a versatile range of equipment available with a comprehensive selection of CFL proprietary metallic and polymeric filters and specialised process internals. This includes a diverse range of filtration and separation components including cartridges, candles, elements, bags and baskets.

Flexible and adaptable filter options ensure that CFL equipment meets the specific requirements of various industrial applications, accommodating distinct filtration and separation needs. CFL standard filter housings are designed to deliver optimal performance.

Expertly engineered for reliability and ease of use, CFL equipment provides a robust and consistent solution for industrial filtration and separation requirements.

Custom Engineered Vessels and Equipment

With a strong track record spanning more than four decades and deep-rooted capability, CFL is a specialist in the design and manufacture of custom filtration and separation equipment, vessels, including process and packaged equipment, supporting projects in oil and gas, hydrogen production, waste to energy, refining and water treatment.

Using our technical ingenuity and expertise, we continuously innovate to efficiently and effectively deliver custom engineered solutions that support the most demanding and safety critical industries.

Our welding manufacturing processes are meticulously controlled and conducted to the highest of standards of quality and consistency in accordance with ISO 3834, along with full compliance to client standards and specifications.

Innovative Engineering for Safety and Performance

With unwavering dedication, we are committed to consistently delivering excellence. We place paramount importance on safety and environmental stewardship in every aspect of our operations. Our commitment is to a future where quality and responsibility go hand in hand.

We design, engineer and deliver.

Applications

- Produced Water Treatment

- Seawater Treatment

- Industrial Water Treatment

- Environmental Control

- Desalination

- Fuel Filtration

- Hydrogen Storage and Distribution

- Precious Metals Recovery

Industries

- Sustainable Energy

- Chemicals

- Fertilisers

- Oil and gas

- Nuclear power

- Pharmaceuticals

- General Process

- Refining

CFL process equipment and products operate in the most demanding and safety critical industries. Our experienced design and technical teams deliver customised solutions, offering enhanced operational performance and productivity, helping to lower operating costs, minimising environmental impact.

High-Capacity Filtration Solution for Southern Water

Southern Water sought a reliable filtration solution to remove suspended particulates to 5 micron. This challenge required high-efficiency filters that could be delivered quickly to meet their urgent operational needs.