Precision Metallic Woven Wire Cloth and Products

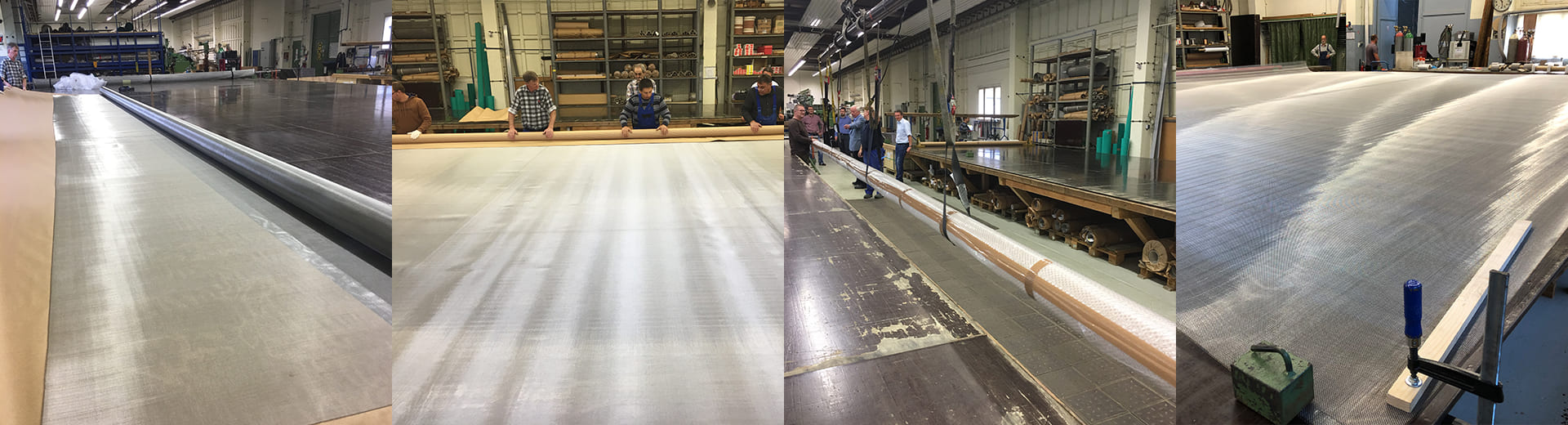

Woven wire cloth is a versatile material with precise specifications and properties manufactured to meet a comprehensive range of industrial, commercial, and scientific applications. With inherent attributes including, strength, durability, flexibility and malleability, woven wire cloth can be shaped, pressed, pleated, laser-cut and fabricated into precise and sophisticated custom parts and components. CFL woven wire cloth supports extensive applications including filtration and separation, fluidising, passive fire protection, noise attenuation, flow control, grading and screening, heat shielding, and aesthetic value to architectural design.

The interweaving of wires forms a metallic mesh structure, with wires running parallel to the length known as the warp, and those running along the width referred to as the weft. CFL mesh products are manufactured in accordance with DIN EN ISO 9044.

With unparalleled expertise and uncompromising quality, our weaving methods and specialist proprietary wires yield a comprehensive range of precision engineered metallic mesh structures. From micronic materials to heavy-duty durable pre-crimped screens, we serve diverse industrial markets and applications, providing expertly engineered solutions to power an ever-changing industrial landscape.

Woven wire cloth and meshes demonstrate excellent performance in high pressure and extreme temperature environments, with excellent resistance to the aggressive and physical stresses of demanding applications. Its inherent versatile properties, and robust fabric quality provides an excellent structure for precisely fabricated parts and components. Specialist materials including C276, C22, titanium, nickel and alloys 400, 600 and 825, provide excellent mechanical strength, thermal resistance and protection against abrasion, erosion and corrosion. Finished product treatments include ultrasonic and thermal cleaning processes, calendering, electropolishing, and solution and vacuum annealing.

CFL has decades of engineering experience and expertise producing world class high integrity specialised parts and components, including nuclear waste containment box filters, sparge tubes, pre-polymerisation, polymerisation and polymer melt filter candles, syngas filters, hydrogen fuel cell electrodes, flame arresters, wind tunnel flow conditioning screens, ballast water filters, spin-pack filters and regenerable filter elements and candles.

Sophisticated filtration and separation solutions offered by CFL play a vital role in ensuring the safe and efficient management of supercritical processes. Our specialist manufacturing processes and materials are designed to guarantee the highest integrity. Our proven track record and commitment to excellence allow us to provide engineered solutions for nuclear power generation and waste storage, pulp and paper production, life sciences, hydrogen production, refining, plastic and rubber production, oil and gas production and defence systems.

Sustainable, High Precision Wire Cloth Products, Supplied with Technical Proficiency

At CFL our focus is sustainable filtration and separation solutions, that positively impact the environment, delivering innovative filter technologies that deliver maximum performance and efficiency. Environmental responsibility, quality, innovation and client satisfaction is ingrained in our DNA.

Key Benefits & Features

- Precision water and laser cutting of complex pieces and parts

- Excellent corrosion and erosion properties

- Precision calendered finished thicknesses

- Mesh openings from 0.01 mm (1 micron)

- Zero absorption of moisture or solvents

- Durable and mechanically stable

- Available in high-value metals

- Zero electrostatic charging

- High abrasion resistance

- Precision apertures

- Ease of fabrication

- High open area

- Excellent pleatabilty, deep drawing and pressing characteristics

- Aesthetic appeal

Industries Served

- Refining

- Oil and gas production

- Aerospace

- Food stuff production

- Pulp and paper production

- Chemical processing

- Hydrogen production

- Life sciences

- Water and waste treatment

- Nuclear generation and waste storage

- Plastics production and plastic recycling

- Gas compression, transfer and processing

- Defense

- Mining and mineral extraction

Specialist Products and Components

With extensive specialist fabrication and production facilities, we convert wire cloth and mesh into various forms and fabricated components including extruder screens, rimmed mesh screens, screen packs, multi-layer screens, cylinders, test sieves, pleated filter elements and baskets, plate and frame pressure filters, spin pack filters, coiled and slit materials, pleat packs, pressed and deep drawn parts, filter candles, pre-coat filters, pressure leaf filters and sieving screens.

For more than four decades we have supported the global automotive and aerospace industries, alongside international wind tunnel test facilities, with specialist flow conditioning screens for subsonic, transonic and supersonic test facilities.

- Standard materials include - Stainless steel grades 304, 316, 321, 310, 347, 410, 430, brass, copper and phosphor bronze.